Design Special designed and developed for high capacity and high head application

Application Transfer ACID / ALKALI / Effluent at higher head & High flow rate.

SpeedThis pump can operate at 1440 RPM as well as 2880 RPM

Recommended ACID effluent transfer for large scale industries.

Scrubbing acidic fumes in steel industries.

|

Temperature Resistance

| PP | 50° | 60°C |

| PPH | 90° | 100°C |

| PVDF | 100° | 110°C |

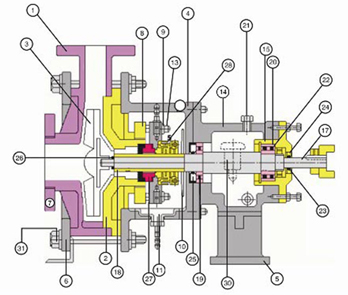

Part List

| Sr. No. | Part Name | M.O.C. |

| 01 | Volute Casing | Polypropylene |

| 02 | Back Plate | Polypropylene |

| 03 | Impeller | Polypropylene |

| 04 | Adopter | Cast Iron |

| 05 | Leg | Cast Iron |

| 06 | Cage Ring | Cast Iron |

| 07 | Suction Flange | Polypropylene |

| 08 | Adopter Flange | Polypropylene |

| 09 | Locating Flange | Hylem |

| 10 | Deflector | Polypropylene |

| 11 | Drip Tray | Polypropylene |

| 12 | Reducer 40 x 40 “ | Polypropylene |

| 13 | Bold For Clamp | P.P. - S.S. |

| 14 | Bearing Housing | Cast Iron |

| 15 | Bearing Cover | Cast Iron |

| 16 | Hard Ware | M. S. Cad Pltd. |

| 17 | Bare Shaft | EN 8 / EN 41 |

| 18 | Shaft Sleeve | Ceramic |

| 19 | Bearing | Steel |

| 20 | Bearing | Steel |

| 21 | Circlip | Steel |

| 22 | Star Washer | Steel |

| 23 | Lock Nut | Steel |

| 24 | Oil Seal (40x25x10) | Neoprene |

| 25 | Oil Seal (72x36x190) | Neoprene |

| 26 | O'ring | Neoprene |

| 27 | Stationary (Mech.Seal) | Ceramic |

| 28 | Rotary (Mech. Seal) | Teflon Bellow |

| 29 | Sleeve Gasket | PTFE |

| 30 | Constant Level Oiler | AL/ABS Plastic |

| 31 | Cage Ring Hard Ware | S.S. 304 |

High Speed Pumps

Pumps Are Recommended For Excellent for scrubbing corrosive and aggressive gases like CI2, Br2, I2, SO2, SO3, CO3, etc. Used in transfer of chemical in batch process. Recommended for use against filter press in dyes and intermediate industries. For recirculation of chemicals in electroplating industries.

Temperature Resistance

| PP | 50° | 60°C |

| PPH | 90° | 100°C |

| PVDF | 100° | 110°C |

|

Pumps Are Recommended For Transferring acids / alkalies / corrosive chemicals Loading and unloading of tankers. Used for effluent treatment Plants for max. 3 mtr. negative suction with foot valve. Used for recirculation of chemicals in electroplating plants and picking plants.

Temperature Resistance

| PP | 50° | 60°C |

| PPH | 90° | 100°C |

| PVDF | 100° | 110°C |

|

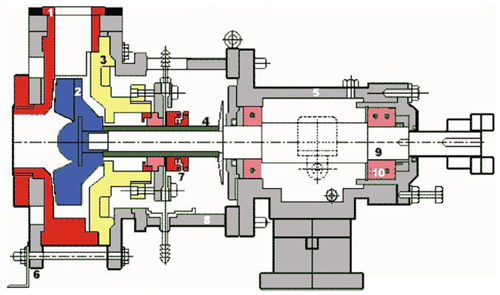

Low Speed Pumps

Standard Pumps fitted with Ceramic Sleeve and Teflon Bellow Mechanical Seals. Excellent for handling corrosive chemicals like HCL, dil H2SO4, NaOH, HNO3, H3PO4, NaCI etc.

Low Speed Series

- DB 50 R

- DB 50

- DB 55

High Speed Series

- DB 160 RL

- DB 160 R

- DB 160

- DB 170

- DB 40

Economy Pumps

Standard Pumps fitted with Ceramic Sleeve and Teflon Bellow Mechanical Seals. Excellent for handling corrosive chemicals like HCL, dil H2SO4, NaOH, HNO3, H3PO4, NaCI etc.

Applications

- Acids, Alkalies Transfer

- Recirculation of Electrolyte

- Scrubbing of Corrosive Gases like CI2, Br2, I2, So2

- Effluent Treatment

- For Descaling of Tubes

- Filteration

Industries

- Chloro Alkali Industries

- Chemical & Pharma Industries

- Electroplating Industries

- Electronic Industries

- Food Industries

Part List

|