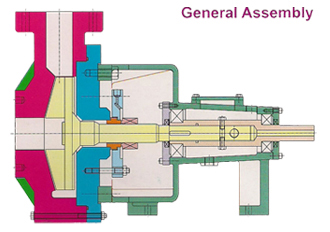

Solid molded spare parts of wear-resistant Ceramic provides durable defense against corrosive environments. "Joint-less, no metal parts in contact area ensures fully corrosion resistance atmosphere.

- All - Ceramic continuos strand, thermoset construction.

- No separate liner concern.

- Integral molded single piece shaft impeller.

- No separate impeller lock nut and gasket.

- No need of separate shaft sleeve.

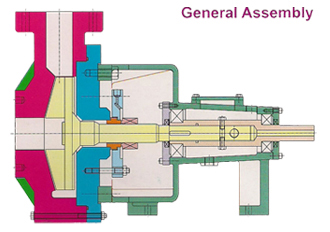

- Modular design for component inter-changeability.

- Back pull-out for easy maintenance.

- Chemical resistant solid Ceramic construction.

- Choice of specialised Teflon Below Mechanical.

- Seal with different face combination with Hastelloy Hardware.